Advantages Of Non-Structural Steel Framing

Light gauge metal stud framing is preferred in many areas of construction due to the comparatively low cost of the materials involved. It is estimated that approximately 60% of the metal studs used in Canada are for interior non-structural wall partitions. Not only does light gauge metal framing offer durability, strength, and stability for wall partitions, it is also: corrosion-resistant, fire-resistant, termite-proof, not susceptible to mould, and made with recycled materials.

Best and acceptable framing practices, innovative steel framing products, and better tools are creating an environment which facilitates producing a quality project while still maintaining high production rates.

Construction Guide For Non-Structural Steel Framing

Won-structural metal studs and framing are not designed or intended to carry any axial loads. Axial loads would include such elements as floor joists, ceiling joists, roof rafters, or roof trusses. They are, however, designed to carry a dead load of many typical wall finishes such as gypsum board, plasterwork, or similar finishes, and to provide resistance to normal transverse loads. Lateral loads cannot exceed 10 lb/sq. ft on a steel-framed wall system as defined by ASTM C645.

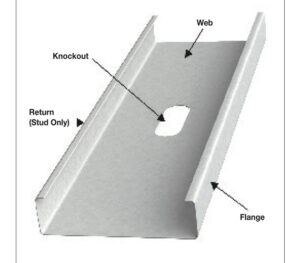

Types of Non-Structural Metal Stud For Construction

ASTM 1003 Standard specification for steel sheet coated and metallic coated for cold-formed framing members

ASTM A653 Standard specification for steel sheet zinc-coated (galvanized) by the hot-dip process

ASTM A792 Standard specification for zinc-coated steel by the hot-dipped process

ASTM C645 Standard specification for non-structural steel framing members

ASTM C754 Standard specification for the installation of steel framing members

ASTM C1047 Standard specification for trims and accessories am text block. Click the edit button to change this text.