When you look at today’s skyline, towering skyscrapers and sleek commercial spaces dominate the view. While concrete and wood have long been part of construction, lightweight metal solutions—like steel framing, metal studs, and light gauge steel systems—are increasingly the top choice for builders and architects. But why is metal preferred for high-rise buildings, and what best practices should be followed to ensure success?

Let’s explore the key benefits of lightweight metal in modern construction, along with examples and best practices.

Why High-Rises Prefer Metal Over Concrete and Wood

1. Strength-to-Weight Ratio

Steel and other lightweight metals offer exceptional strength without the heavy bulk of concrete. For high-rise buildings, reducing weight is crucial to limit the load on the foundation and minimize structural stress. Metal framing provides the perfect balance of durability and lightness, allowing architects to design taller, slimmer, and more ambitious buildings.

2. Speed and Efficiency

Time is money in construction. Metal framing systems are pre-engineered, easy to transport, and fast to install compared to concrete pouring or wood framing. With factory-cut precision, metal components reduce on-site waste and lower the risk of delays, keeping projects on schedule.

3. Fire Resistance and Safety

One of the top concerns in high-rise construction is fire safety. Steel and metal studs are naturally non-combustible, making them a safer option than wood. Many building codes even require steel framing in commercial and high-rise spaces to meet fire safety standards.

4. Sustainability and Green Building

Lightweight metals like steel are highly recyclable, which helps reduce the environmental footprint of new buildings. Many developers use recycled steel to earn points toward LEED certification and other green building standards, appealing to environmentally conscious tenants and investors.

5. Design Flexibility

With metal framing, architects can achieve open floor plans, larger window spans, and creative facades that are difficult or impossible with wood or concrete. Metal solutions support innovation in design while maintaining structural integrity.

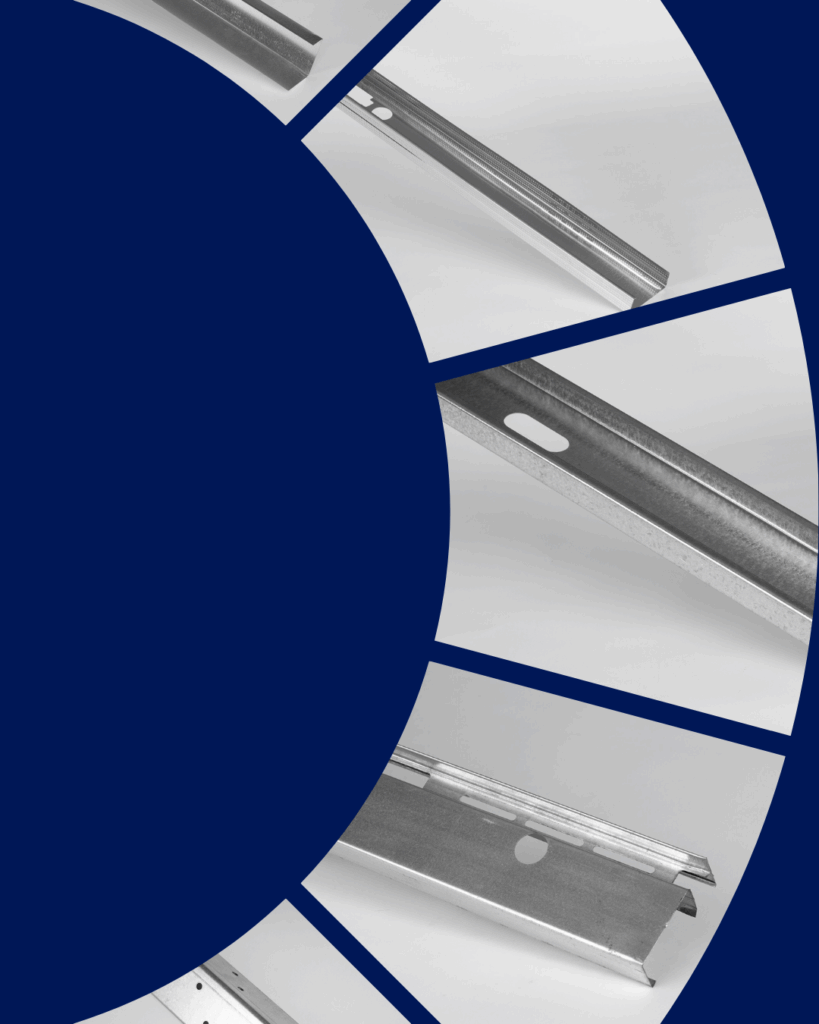

Our Case Study: Dass Metal Products Projects

Dass Metal Products supply lightweight steel framing for mid-rise and high-rise commercial projects across Canada and the US. With CSSBI-certified metal studs and framing systems, Dass Metal Products ensures builders get high-quality, durable materials that meet project demands.

Best Practices for Using Lightweight Metal in High-Rise Construction

- Work with Certified Suppliers : Always source metal framing and studs from certified manufacturers like Dass Metal Products to ensure quality, durability, and compliance with building codes.

- Engage in Early Planning: Coordinate with architects, engineers, and contractors early in the design phase. This ensures the metal framing system is integrated seamlessly into the project.

- Use Skilled Installers : Lightweight metal framing requires experienced installers who understand its unique properties and can execute the design accurately.

- Consider Fireproofing and Insulation : Even though steel is fire-resistant, adding proper insulation and fireproof coatings can enhance building safety and energy efficiency.

- Focus on Sustainability : Choose recycled steel and metal components to support green building initiatives and reduce the project’s environmental impact.

Final Thoughts

Lightweight metal solutions have revolutionized the way we build high-rise buildings. With benefits like unmatched strength, fire safety, speed, and sustainability, it’s no wonder that skyscrapers and commercial projects around the world rely on steel framing over traditional concrete or wood.

If you’re looking to source top-quality metal products for your next project, consider Dass Metal Products—a trusted supplier of CSSBI-certified steel framing and metal studs across North America.